Brief Introduction to 230mm Electric Concrete Pump

Concrete pump is a machine used for transferring liquid concrete by

pumping to different heights as per the requirements. The

stationary pump has a superior S-valve technology which is

considered to be efficient and advanced method used for pumping.

S-valve can pump concrete with high pressure which helps in

concrete reaching easily at higher elevations, switching between

the cylinders for delivering concrete increases the productivity

and also distributes the pumping of concrete equally in 2

cylinders.

The HBT80 with a maximum capacity of 80 cubic meters per hour, is

equipped with a unique hopper and blade design to reduce material

residues and facilitate cleaning.Suitable for various concrete

formulations.Good maintainability, easy to repair and disassemble.

Parameters of 230mm Electric Concrete Pump:

Item | HBTS80-16-110 |

Max Theoretical Concrete Output | 50/85 m3/h |

Max Theoretical Conveying Distance (vertical Height/Horizontal Distance) | 270/1200 m |

Max Concrete outlet Pressure | 16 Mpa |

Distribution Valve | S Valve |

Max Aggregate size | 30 mm |

Concrete Slump | 100~200 mm |

Concrete Cylinder Diameter | φ200×1800 mm |

Oil Tank Diameter | φ140×φ90×1800 mm |

Hopper Capacity/Filling Height | 0.5/1400 m3/mm |

Concrete Pumping Pressure | 30 Mpa |

Hopper Mixing Pressure | 16 Mpa |

Oil Tank Capacity | 200 L |

Cleaning Mode | High Pressure Washing |

Motor | 110 kw |

Oil Pump | Double 140ml/r (Korea KAWASAKI) |

Valve Group | Germany Bolseen |

Hydraulic Hose | Italy MANULI |

Electric | CHNT/Schneider |

Dimension (L×W×H) | 7125×1980×2300 mm |

Weight | 6200 kg |

The Working of 230mm Electric Concrete Pump

The basic principle of working of all types of concrete pumps is

the same. The pump operates on the basis that one piston draws

liquid concrete from a hopper into a cylinder while the other

piston pushes its concrete out into the discharge pipes, both the

functions happening simultaneously. There is a valve that controls

which cylinder opens to the concrete hopper and which one opens to

the discharge pipes. The valve switches every time the pistons

reach the end point, and the process goes on with the first

cylinder now releasing the concrete and the second cylinder drawing

fresh concrete from the hopper.

The piston concrete pump vehicle is to charge the ready mixed

concrete into the cylinder through the hopper when the pistons are

contracted, and to discharge when the pistons are expanded, like

water guns. Charging and discharging operations are switched by the

swing valve.

| 1. Hydraulic system

Double open hydraulic loops with 2 pumps.The reliability of the

whole system is also much higher as well as the components' life is

prolonged greatly. This is convenient for judgeing and removing

trouble.

|

2. Electric control system

Compared with domestic product, the electric control system is

simplest, the element quantity is fewest and its reliability is the

highest.

Adopting proximity switch in hydraulic cylinder can realize

changing direction with non-touch, which ensures that the direction

can be changed reliably.

|

|

| 3. Mechanical system

The design of hopper and S valve and so on adopt I-DEAS software to

caculate, the hopper and S valve have good rigidity to avoid the

phenomenon of hopper distortion and S valve breakage.

|

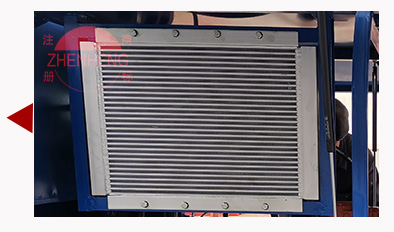

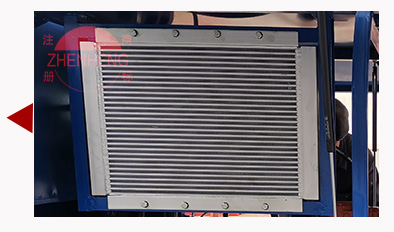

4. Cooling system

The radiator equipment makes the working oil temperature of

hydraulic system below 70℃ and makes the machine in normal status.

|

|

Features to 230mm Electric Concrete Pump:

1. Concrete flows constantly into cylinder from bottom of hopper,

which shall enable to get high suction efficiency. Air intrusion

shall be shut out by polyurethane packing.

2. Our concrete pump has parallel twin cylinder mechanism , which

shall make concrete push out straight in beeline. There is no

change of cross section space, shape, and direction of concrete

flow, which shall reduce discharge resistance.

3. High suction efficiency, air tightness and low discharge

resistance avoid paste separation and air Intrusion, then it makes

little change of properties of concrete.

4. Outstanding mobility, and highest pumping out-put among

line-ups.

Warranty:

The warranty will be one year from the date of shipment. Any

detected parts during this period caused by the quality of products

will be replaced by seller free of cost (exclude wear and tear

parts), improper operation and other manmade reasons are

excluded.and engineers available to service machinery overseas.

Our Services

1. With the fastest speed to make the quotation for customers on

the prerequisite that we are clear to capacity, quantity,

automation requirement, spare parts requirement (Chinese Top Brands

or World Grade Brands like Siemens Motors etc), wearing parts

requirement,delivery terms etc.

2. Bottom Price for customer as much as possible.

3. Flexible Payment Terms.

4. Offering the analysis of ROI(Return of Investment).

5. 1-3 short training periods, 10-15 days installation,1-2days

commission,1-2days pre-operation.

6. Total service fees below USD90 for one engineer in one day

compared with markets trends USD120.00

7. Shortest periods of processing and manufacturing. For single

machines, at most 5days;for production line,at most 15days.