Brief Introduction to Ready Mixed Concrete Mixing And Pumping

Machine Material Saving Easy Overhauling

The concrete pump is composed of pump body and delivery pipe. It is

a kind of machinery that continuously transports concrete along the

pipeline by using pressure. It is mainly used for house

construction, bridge and tunnel construction.

The HBT80 with a maximum capacity of 80 cubic meters per hour, is

equipped with a unique hopper and blade design to reduce material

residues and facilitate cleaning.Suitable for various concrete

formulations.Good maintainability, easy to repair and disassemble.

Parameters of Ready Mixed Concrete Mixing And Pumping Machine

Material Saving Easy Overhauling:

Item | HBTS80-16-110 |

Max Theoretical Concrete Output | 50/85 m3/h |

Max Theoretical Conveying Distance (vertical Height/Horizontal Distance) | 270/1200 m |

Max Concrete outlet Pressure | 16 Mpa |

Distribution Valve | S Valve |

Max Aggregate size | 30 mm |

Concrete Slump | 100~200 mm |

Concrete Cylinder Diameter | φ200×1800 mm |

Oil Tank Diameter | φ140×φ90×1800 mm |

Hopper Capacity/Filling Height | 0.5/1400 m3/mm |

Concrete Pumping Pressure | 30 Mpa |

Hopper Mixing Pressure | 16 Mpa |

Oil Tank Capacity | 200 L |

Cleaning Mode | High Pressure Washing |

Motor | 110 kw |

Oil Pump | Double 140ml/r (Korea KAWASAKI) |

Valve Group | Germany Bolseen |

Hydraulic Hose | Italy MANULI |

Electric | CHNT/Schneider |

Dimension (L×W×H) | 7125×1980×2300 mm |

Weight | 6200 kg |

The Working of Ready Mixed Concrete Mixing And Pumping Machine

Material Saving Easy Overhauling:

The basic principle of working of all types of concrete pumps is

the same. The pump operates on the basis that one piston draws

liquid concrete from a hopper into a cylinder while the other

piston pushes its concrete out into the discharge pipes, both the

functions happening simultaneously. There is a valve that controls

which cylinder opens to the concrete hopper and which one opens to

the discharge pipes. The valve switches every time the pistons

reach the end point, and the process goes on with the first

cylinder now releasing the concrete and the second cylinder drawing

fresh concrete from the hopper.

Features to Ready Mixed Concrete Mixing And Pumping Machine

Material Saving Easy Overhauling:

1. Suitable for high pressure operations

The valve, realized its airtight and well balanced pressure,

enabled smooth pumping operations by stabilizing its switching

function even at high pressure.

2. Saving running cost

The valve has few parts and its structure is the utmost in

simplicity.

Realized easy cleaning by reducing the remaining ready mixed

concrete.

The direct suction system uniting the valve and the hopper eases

introducing of the volume.

The bottom flap mechanism with which the hopper bottom opens widely

saves troubles in removal of the remaining ready mixed concrete.

Newly designed hydraulic circuits with excellent reliability and

durability

The valve is equipped with newly designed hydraulic circuits

employing logic sequencing. These high quality hydraulic components

increase reliability and durability. High pressure pumping can be

started by switching the hydraulic circuits and this is suitable

for pumping to high places and over long distances.

3. User serviceability

The simple valve structure facilitates inspection, adjustment and

replacement of consumable parts, and also enables easy overhauling.

User servicing is also possible.

4. Elbow with wear detecting holes

Our concrete pump elbow pipes, made of quench casting materials,

have wear detecting holes archiving durability, improves safety,

and smoothen the ready mixed concrete flow.

5. Control panel

The control panel is installed at the position of being visible and

operable easily.

6. Auto lubricator

The automatic lubricator is equipped, which greases quantitatively

during pumping operations.

More details of Ready Mixed Concrete Mixing And Pumping Machine

Material Saving Easy Overhauling

| 1. Hydraulic system

Double open hydraulic loops with 2 pumps.The reliability of the

whole system is also much higher as well as the components' life is

prolonged greatly. This is convenient for judgeing and removing

trouble.

|

2. Electric control system

Compared with domestic product, the electric control system is

simplest, the element quantity is fewest and its reliability is the

highest.

Adopting proximity switch in hydraulic cylinder can realize

changing direction with non-touch, which ensures that the direction

can be changed reliably.

|

|

| 3. Mechanical system

The design of hopper and S valve and so on adopt I-DEAS software to

caculate, the hopper and S valve have good rigidity to avoid the

phenomenon of hopper distortion and S valve breakage.

|

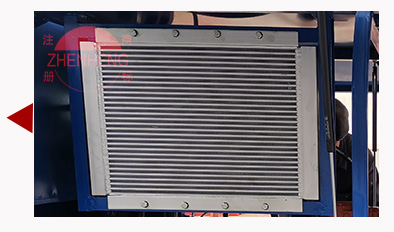

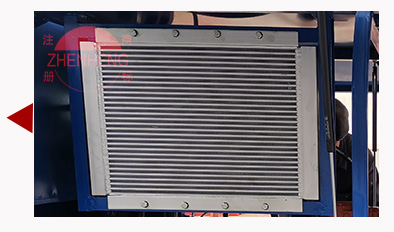

4. Cooling system

The radiator equipment makes the working oil temperature of

hydraulic system below 70℃ and makes the machine in normal status.

|

|

Warranty:

The warranty will be one year from the date of shipment. Any

detected parts during this period caused by the quality of products

will be replaced by seller free of cost (exclude wear and tear

parts), improper operation and other manmade reasons are

excluded.and engineers available to service machinery overseas.

Our Services:

1. Well-trained and experienced staff to answer all your inquiries

in fluent English and Russia.

2. We will send our professional engineers to you country and help

install the pump , train your worker to operate the pump.

3. OEM & ODM is welcome. OEM brand is available.

4. If you have any idea or demand, we can provide the customization

service.

5. Protection of your martket area, ideas of design and all your

private information.

6. We will supply the spare parts to insure the quality of our

pump.

7. Your inquiry will be replied within 24 hours.

8. Provide following up after-sales services. We will dispatch our

serviceman to solve the problem for you, if you have questions

about our pump.